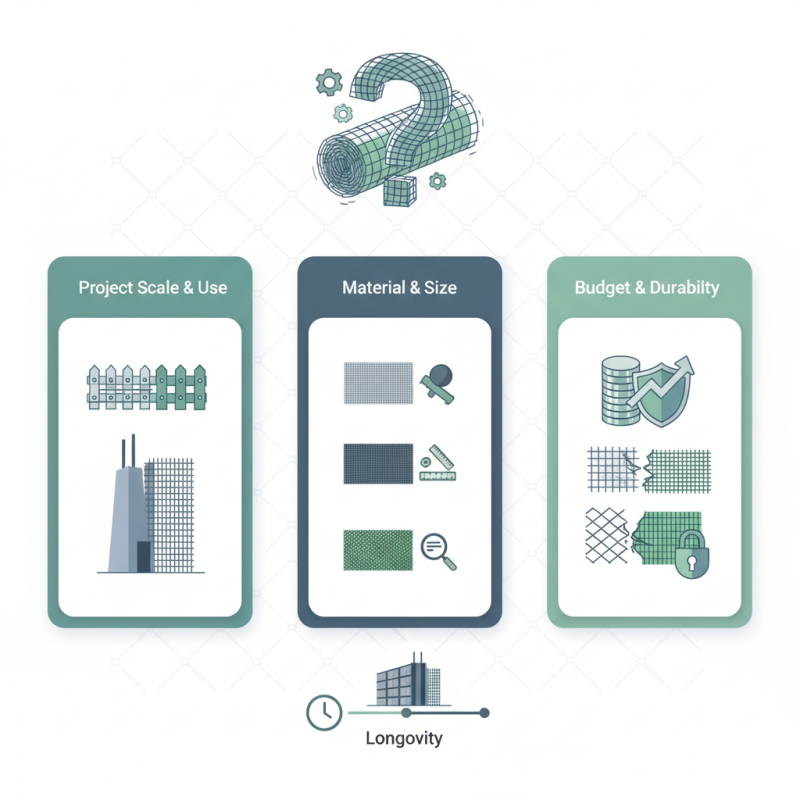

How to Choose the Right Welded Wire Mesh for Your Project?

Choosing the right welded wire mesh for your project can be challenging. "Welded wire mesh is essential for various applications," says industry expert John Smith, who has decades of experience in this field. Selecting the correct type can significantly impact the integrity and success of your project.

welded wire mesh comes in different sizes and materials. You need to understand your specific requirements. Consider the project scale and intended use. For instance, a construction site may need a heavier gauge compared to a simple garden project.

It's also vital to reflect on your budget. Higher quality welded wire mesh offers durability and strength but may cost more. Sometimes, opting for the cheapest option leads to failures. Analyze your options carefully. Your choice of welded wire mesh will determine how well your project withstands the test of time.

Understanding Welded Wire Mesh: Types and Specifications

Welded wire mesh is versatile. It's commonly used in construction, agriculture, and fencing. Understanding its types and specifications is crucial for making the right choice.

There are several types of welded wire mesh. Each type has unique characteristics. For example, some have a finer wire diameter. This can be beneficial for certain applications like animal enclosures. Others have larger openings, which might suit different needs, such as drainage or reinforcing concrete. You might find it tricky to decide which type fits your project best.

Specifications are also key. Look for mesh size, wire gauge, and material. A thicker wire often means better strength but can be harder to handle. Consider the environment too. Rust-resistant options might be better for outdoor use. Reflect on your project's specific demands, as overlooking details can lead to issues later. Balancing strength and flexibility is vital, yet it often requires careful thought.

Key Factors to Consider When Selecting Welded Wire Mesh

When selecting welded wire mesh for your project, consider several key factors. The wire gauge matters significantly. Thicker wires provide enhanced strength. However, they are heavier and may be more challenging to work with. Choosing the right gauge for your specific application is crucial.

The size of the mesh openings is another important aspect. Smaller openings offer better support for lighter materials. Yet, they may limit airflow or visibility in certain applications. On the contrary, larger openings allow for greater airflow but might not provide the same level of support.

Tips:

1. Always visualize how the mesh will integrate with your overall design.

2. Think about the project’s environment. Will it face moisture or chemicals? These factors influence mesh durability.

3. Check for any specific regulations in your area related to welded wire mesh.

Also, reflect on the aesthetics. The finish of the mesh can affect its appearance, which is vital for visible applications. You might choose a galvanized finish to prevent rust, but it alters the look. Balancing function and visual appeal is often a complex decision.

Applications of Welded Wire Mesh in Construction and Agriculture

Welded wire mesh is widely used in construction and agriculture. In construction, it provides stability and support. The global welded wire mesh market is projected to reach $8.9 billion by 2027, driven by its essential role in reinforcing concrete structures. Steel wire mesh contributes to the durability of buildings. It effectively resists cracking and shifting under pressure.

In agriculture, welded wire mesh serves multiple functions. Farmers use it to create enclosures for animals. It protects crops from pests, deer, and other wildlife. The mesh is robust yet adaptable. Reports show that the agricultural wire market will grow as sustainable farming practices increase. Some may overlook the importance of selecting the right gauge. Each project requires specific strength. The wrong choice can lead to additional costs and safety issues.

Manufacturers need to consider local environmental factors when producing welded wire mesh. Different climates and soil conditions can impact performance. Some products may rust or degrade faster than expected. Research indicates that proper maintenance can extend the lifespan. Using the right materials is crucial for long-term success. Always evaluate the specifications before making a decision.

How Wire Gauge and Diameter Affect Mesh Strength and Durability

When selecting welded wire mesh, understanding wire gauge is crucial. The gauge indicates the thickness of the wire used. Thicker wires, higher gauge numbers, generally offer more strength. This is vital in applications like fencing and construction. However, heavier wire can be harder to handle. It can also be more expensive. Balancing strength and ease of use is important.

Diameter also plays a key role in mesh durability. A wider diameter means a stronger mesh. Yet, it can add unnecessary weight. For projects requiring more flexibility, a smaller diameter could be favorable. For instance, when considering installation in tight spaces, lighter mesh is essential.

Reflecting on the specifics of each project is crucial. Will the mesh be exposed to harsh conditions? If so, then a thicker wire might be necessary. Yet, if it's being used for decorative purposes, aesthetic factors may take precedence. Choosing the right welded wire mesh involves careful consideration of both gauge and diameter. Each project dictates unique needs, and sometimes, it’s easy to overlook critical details.

Welded Wire Mesh Strength Comparison

The chart above compares the strength of different welded wire mesh gauges. As the gauge number increases, the strength of the mesh typically decreases, indicating that lower gauge numbers provide higher durability and support for various projects.

Cost Analysis: Budgeting for Your Welded Wire Mesh Project

When budgeting for a welded wire mesh project, it’s crucial to understand your needs. Analyze the scope of your project first. How much area do you need to cover? Different applications require different specifications. The dimensions and wire gauge will significantly impact the cost.

Consider the material quality as well. Not all welded wire mesh is made equal. A higher quality mesh may have a higher upfront cost, but it could save you money in the long run due to its durability. Analyze your environment. If it's harsh, investing in better materials could prevent future expenses.

Tips: Always get multiple quotes. Prices can vary widely. Don’t forget to consider delivery fees. Factor in installation costs too. Sometimes hiring professionals is worth the investment.

You might find yourself reassessing your budget as you gather more information. Unexpected expenses can arise. Keep a contingency fund. It’s often overlooked but can be a lifesaver in tight situations. Don't rush the process; thorough planning can prevent costly mistakes later.