What is a Rubber Air Hose and How Is It Used?

In the world of pneumatic tools, the rubber air hose holds a vital place. Experts like John Smith, a leading figure in the air hose industry, emphasize its significance, stating, "A rubber air hose is essential for high-performance tools." This statement reflects the crucial role that these hoses play in various applications.

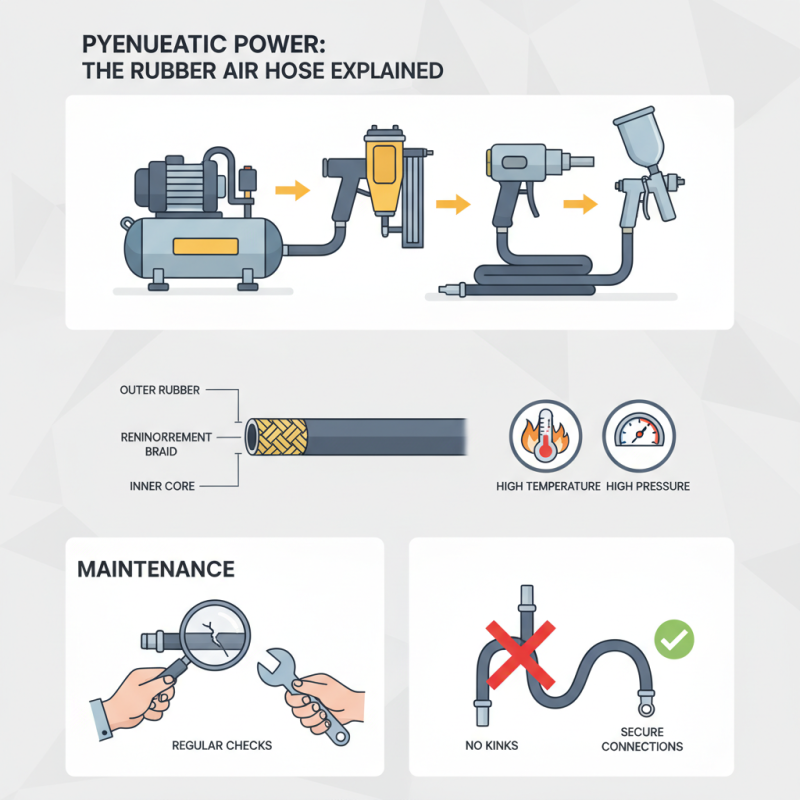

rubber air hoses are designed for durability and flexibility. They can withstand high pressures and extreme temperatures. Users rely on them to connect compressors to tools securely. However, not all rubber air hoses are created equal. Some may wear out quickly or kink under pressure. This makes choosing the right one essential.

Beyond functionality, there’s a need for awareness about maintenance. Regular checks can prevent air leaks or ruptures. Ignoring these needs can lead to inefficiency or even accidents in the workplace. The rubber air hose, while simple in design, demands respect for its capabilities and limitations. Understanding these elements fosters better usage and enhances safety.

What is a Rubber Air Hose and Its Composition

Rubber air hoses are essential tools in various applications, from automotive repairs to industrial uses. They are made from synthetic or natural rubber, ensuring flexibility and durability. The composition often includes various chemicals, making them resistant to wear and tear. A common choice for air compressor systems, these hoses can withstand high pressure.

When choosing a rubber air hose, consider its size and pressure rating. Ensure it fits your air compressor. Look for hoses with a smooth inner lining; this reduces friction and increases airflow efficiency.

Tips: Regularly inspect your hose for any signs of wear. A worn hose may burst under pressure. Also, avoid kinking it during use. Kinks restrict airflow, leading to inefficiencies. Storing your hose properly will extend its lifespan. Make sure to coil it without tight bends.

Rubber Air Hose Characteristics

Common Applications of Rubber Air Hoses in Various Industries

Rubber air hoses are vital in various industries. They are durable and flexible, making them ideal for handling compressed air. In manufacturing, these hoses transport air efficiently. Compressed air is essential for powering tools and equipment. Reports indicate that the global air hose market is expected to grow steadily, reaching over $1 billion by 2025. This reflects the increasing demand across sectors like automotive and construction.

In the automotive industry, rubber air hoses aid in assembling engines and pneumatic braking systems. They're lightweight, allowing easy maneuverability. However, users often overlook routine maintenance. This can lead to premature wear and reduced efficiency. In construction, these hoses connect air compressors to pneumatic tools. Their high resistance prevents kinking, ensuring a steady airflow. Yet, job site conditions can be harsh. Exposed hoses might crack or degrade faster than expected.

Rubber air hoses are also used in agriculture. They handle tasks such as powering irrigation systems and sprayers. The need for reliable equipment is critical here. However, many farmers report issues with improper fittings. This can lead to air leaks, wasting resources and time. Proper training on hose management would be beneficial. It's clear that while rubber air hoses play a crucial role, awareness of best practices is essential for optimal performance.

What is a Rubber Air Hose and How Is It Used? - Common Applications of Rubber Air Hoses in Various Industries

| Industry | Common Applications | Advantages of Rubber Air Hoses |

|---|---|---|

| Construction | Powering pneumatic tools such as nail guns and jackhammers | Durability and flexibility in tough environments |

| Automotive | Inflating tires and powering air tools in workshops | Resistant to oil and abrasion |

| Agriculture | Filling air tanks for spraying equipment | Excellent weather resistance |

| Manufacturing | Operating pneumatic machinery in factories | High elasticity and tensile strength |

| Marine | Used in air brake systems and compressors | Resistant to saltwater and UV exposure |

Key Advantages of Using Rubber Air Hoses Over Other Materials

Rubber air hoses are essential tools in various industries. They are flexible, durable, and reliable. Their design allows them to withstand high pressure and temperature variations. Unlike hoses made from PVC or other materials, rubber hoses are less likely to crack or become brittle. This flexibility enhances their usability.

One key advantage of rubber air hoses is their resistance to environmental factors. They can endure UV rays and extreme temperatures without degrading. This makes them suitable for outdoor and industrial applications. In addition, rubber hoses often feature better abrasion resistance. They resist wear and tear over time, ensuring longevity.

Tip: Always inspect your rubber hose for any signs of damage. Look for cracks or leaks before each use. Proper storage is important too. Keep your hose away from sharp objects and extreme temperatures.

Another advantage is the enhanced grip they provide. When working in wet or oily conditions, rubber hoses reduce the risk of accidental slips. This adds a layer of safety during operation. However, be aware that they can be heavier than other materials. Choose the right length and thickness for your needs.

Tip: Consider the weight of the hose when selecting it for a task. A lighter hose may be more manageable, especially for repeated use.

Performance Characteristics: Pressure Ratings and Temperature Resistance

Rubber air hoses are widely used in various applications, including construction and automotive repair. Their performance characteristics are largely defined by pressure ratings and temperature resistance. A standard rubber air hose can typically handle pressures between 125 to 300 psi. It's essential to select a hose that matches the required pressure for your tasks. Exceeding the pressure can lead to failures, which might cause safety hazards and costly repairs.

Temperature resistance is another critical aspect. Most rubber air hoses can withstand temperatures ranging from -40°F to 200°F. This range makes them suitable for both hot and cold environments. However, extreme temperatures can weaken the material over time. You might notice aging signs, like cracks or stiffness. Regular inspection of your hoses is vital. Ensure they are in good condition to maintain performance. Taking care of these details can save you from unexpected breakdowns during crucial work.

Maintenance Tips for Extending the Lifespan of Rubber Air Hoses

Rubber air hoses are essential tools in various industries. They provide flexibility and durability. However, to maximize their lifespan, proper maintenance is crucial. Regular inspection for wear and tear will help identify issues early. Look for cracks or punctures frequently. A damaged hose can lead to air leaks or failures during critical tasks.

Storing rubber air hoses properly can significantly extend their life. Avoid leaving them in direct sunlight for long periods. Heat can degrade rubber over time. Instead, coil the hoses loosely and store them in a cool, dry place. If you notice kinks or twists, take a moment to unravel them. These imperfections can weaken the hose and lead to problems later on.

Additionally, cleaning the hoses after use is beneficial. Dust and grime can accumulate, which may affect performance. Use a damp cloth to wipe them down. Avoid harsh chemicals that could damage the rubber material. While these simple steps seem obvious, many overlook them in daily routines. Prioritizing these actions can ultimately save time and money, ensuring your rubber air hoses work effectively for longer.